ERP Industry – CAPM Module

Take full control of your industrial production.

Are you an industrial SME or mid-sized company and want to manage your production with precision? The CAPM module of our ERP has been designed for respond to concrete challenges on the ground : optimal scheduling, realistic planning, reliable activity monitoring and measurable performance.

Concrete benefits for your industrial company

Total control of your production, in real time

Track every manufacturing step, from raw material to finished product, with a complete traceability and instant control of operations. Meet quality, compliance and audit requirements at any time.

Reduced time and costs

Plan more accurately, avoid shortages, maximize resource utilization, and reduce waste. With our integrated CAPM module, you can improve your overall industrial performance.

Industry 4.0 within your reach

Connect your shop floor in real time with native MES integration: automatic production data collection, performance analysis (OEE, downtime, rejects) and immediate corrective actions

Synchronization and scalability across the entire chain

Streamline your exchanges thanks to native EDI (customers, suppliers, subcontractors) and benefit from a modular and scalable ERP solution that adapts to your industrial growth.

Key Features of the CAPM module

Intelligent MRP Planning

Calculate your net requirements based on orders and forecasts, optimize your stocks (pull flows, CMY, multi-calculations) and anticipate shortages for smooth production.

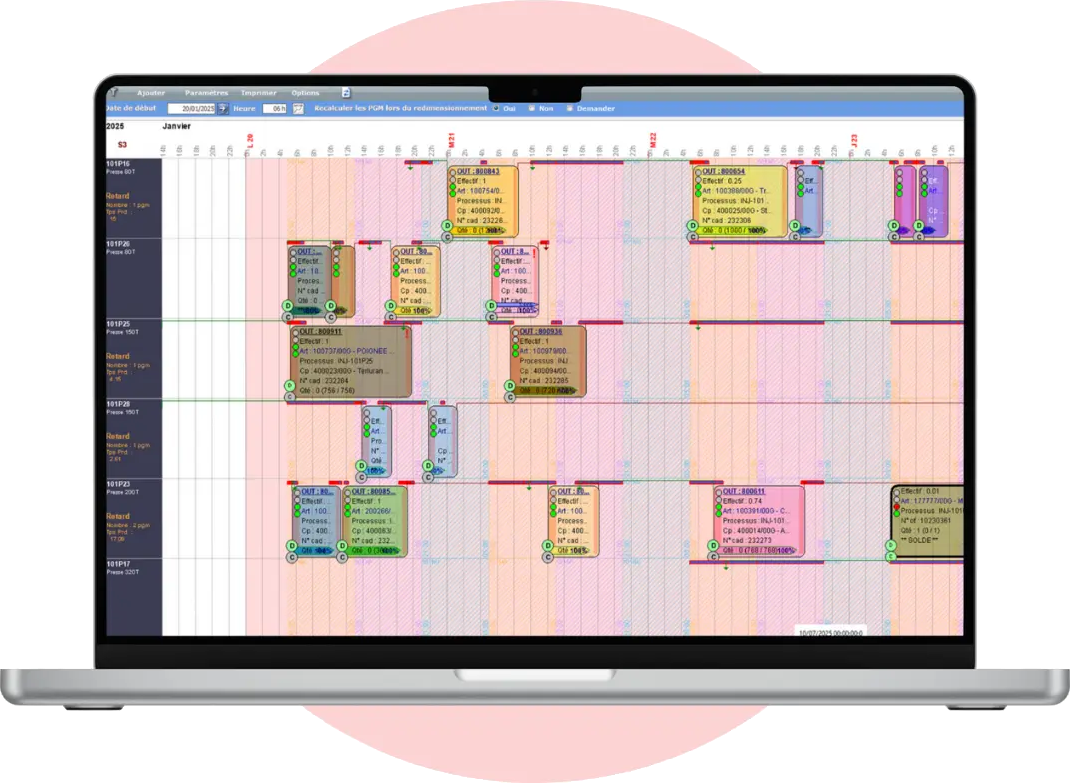

Visual and agile scheduling

Production management: align capacities and commitments

Plan your production short term (1 to 2 weeks), allocate resources precisely (materials, labor, equipment) and manage your manufacturing orders. The module allows you to follow up on your commitments, to anticipate shortages And to ensure consistent management between demand and your actual capacities.

Real-time production monitoring: measure, correct, improve

The module automatically collects the workshop data (quantities produced, rejects, stops, operator times), calculates the key indicators (TRS, TQ, TRO) And analyzes the causes of non-performance. With the optional integration of the MY, you gain access to complete production supervision and engage in a continuous improvement process.

Why our GALION ERP is distinguished

Integrated ERP 100 %

No more re-entry or duplication — all your production data is centralized and accessible in real time.

Publisher-integrator approach

A unique team to develop, deploy and adapt your ERP to your specific needs.

Native EDI & optional MES

Automate your flows with your partners using EDI, and move to the connected factory with the integrated MES.

Business modularity

Start with the essentials, evolve according to your needs (stocks, CMMS, quality, etc.).

Concrete example: Automotive industry

An automotive supplier, faced with tight deadlines and high quality requirements, implemented our CAPM:

- Production times reduced by 15

- Scrap reduced by 8 %

- Improved customer service rate of 12 %

Thanks to our dynamic scheduling and to the real-time activity tracking, this SME has gained in reactivity, in reliability and in profitability.

Ready to digitize your industrial sales?

Optimize your flows today.

Also discover: ERP EDI

Make informed decisions

Analyze your performance with powerful decision-making tools.

- KPIs & custom dashboards

- Dynamic reports

- Native Microsoft Power BI integration