Introduction

In an industrial context marked by digitalization, competitiveness depends on the ability of companies to effectively manage their processes. To this end, two types of software solutions are often mentioned: the ERP (Enterprise Resource Planning) and the CAPM (Computer-Aided Production Management). Although they share certain objectives, their functional scopes, architecture and strategic impact differ profoundly.

This article offers you a clear and expert comparative analysis to help you make the right choice for your ERP project.

ERP vs. CAPM: Comparative Table

| Criteria | ERP (Enterprise Resource Planning) | CAPM (Computer-Aided Production Management) |

|---|---|---|

| Objective | Manage all company processes | Optimize production management |

| Functional scope | Global: purchases, sales, stocks, production, quality, etc. | Specific to production planning, scheduling and monitoring |

| Target audience | General management, CFO, IT department, industrial management | Production, planning, workshop manager |

| Scalability | Modular, interconnected, multi-site, multi-company | Less scalable, often limited to a workshop perimeter |

| Integration | Strong interconnection between services | Often isolated from other functions of the company |

| Examples of modules | CRM, CMMS, MES, WMS, BI, EDI | CBN, PDP, PIC, OF, TRS |

CAPM: a specialized solution for production

Historically, CAPM was designed to meet the specific needs of production workshops. It allows for the planning of manufacturing orders, the tracking of production times, the management of raw material inventories and the monitoring of industrial performance (OEE, scrap rate, etc.).

It is particularly suited to industrial SMEs that wish to structure their production without transforming their entire information system. However, CAPM often remains confined to a limited functional scope, which can create information silos between departments.

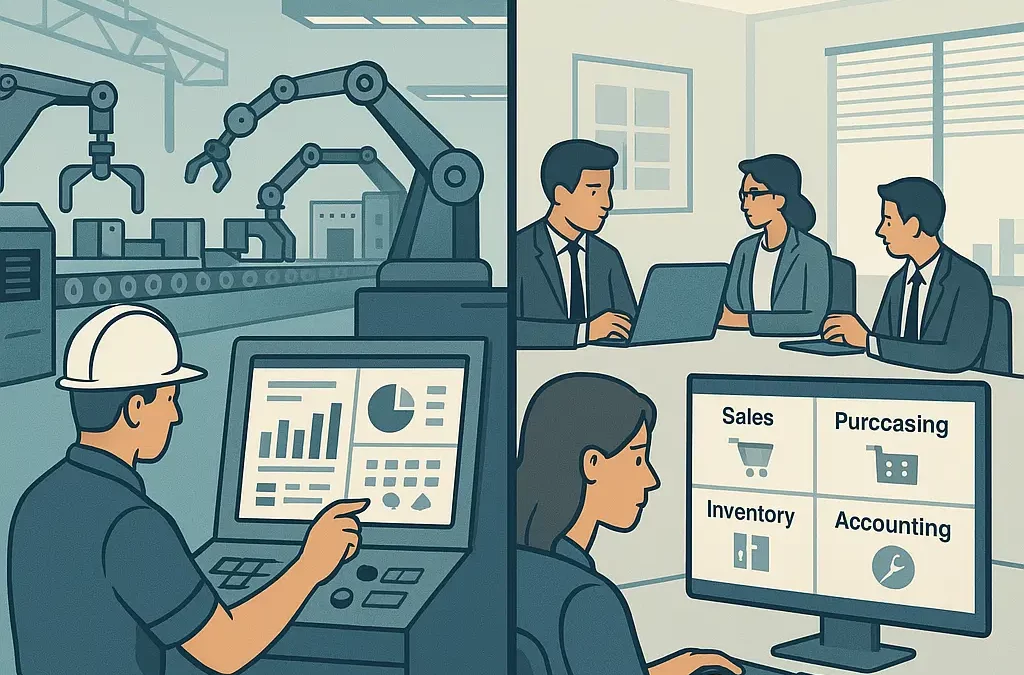

ERP: a global and strategic vision

ERP, on the other hand, is an integrated system that covers all of a company's functions. It allows for centralizing data, automating processes, and streamlining the flow of information between departments.

A modern ERP generally includes a CAPM module, but goes well beyond:

- It connects production to finance, purchasing, logistics, quality, and even maintenance and human resources.

In an ERP project, the goal is to create a single digital backbone capable of supporting growth, improving traceability and strengthening decision-making.

Why ERP is tending to replace CAPM

Key Benefits of ERP

- Unified vision: ERP provides a real-time overview of operations, inventory, orders and performance indicators.

- Reduced errors: By eliminating manual re-entry and multiple interfaces, ERP improves data reliability.

- Agility: thanks to its modularity, the ERP adapts to changes in the company (new sites, new products, external growth).

- Compliance: ERP facilitates compliance with quality, environmental and regulatory standards through complete traceability.

- Strategic management: integrated dashboards allow precise monitoring of industrial and financial KPIs.

Use cases: when to choose one or the other?

Choices adapted to the context

- Single-site SME with simple production: a CAPM system may be sufficient in the short term, particularly if the other functions are managed via office tools.

- Mid-sized companies or multi-site industrial groups: an ERP is essential for structuring processes, harmonizing practices and supporting growth.

- Regulated industry or with high quality requirements: the ERP ensures complete traceability, from raw material to finished product, which is essential for audits and certifications.

ERP project: a lever for transformation

An ERP project isn't just a simple tool change. It's a true transformation project, involving process overhaul, change management, and a long-term vision.

Keys to success

- Define a clear roadmap

- Involve the professions from the framing phase

- Choosing an ERP adapted to your industrial sector

- Rely on an experienced integrator

- Plan for post-deployment support

Conclusion

CAPM is a specialized, effective solution for structuring production. ERP, on the other hand, is a comprehensive solution designed to manage the entire company. In an increasingly connected industrial world, ERP is emerging as a strategic tool for increasing agility, competitiveness, and resilience.

The right choice will depend on your digital maturity, your growth ambitions, and your ability to drive change. But one thing is certain: to ensure the success of your ERP project, it's essential to understand the differences between ERP and CAPM.

Looking for an ERP for your business?

Read next

ERP / PGI: the complete 2025 guide for industrial SMEs

An industrial ERP centralizes an SME's key data, improves traceability, optimizes production, and facilitates decision-making. This practical guide answers key questions managers have about how to successfully implement their ERP project and improve efficiency.

Point-by-Point Production Startup at Vision Systems

Hello everyone, 🙋♂️ 🙋♀️ Vision Systems, a division of Gauzy, is a company based in France and the United States. It designs products and...

Business focus

Hello everyone, 🙋♂️ 🙋♀️➡ Today, focus on our company. GALION SOLUTIONS is a publisher and integrator of an ERP - PGI software solution....