ERP Industry – Quality Module

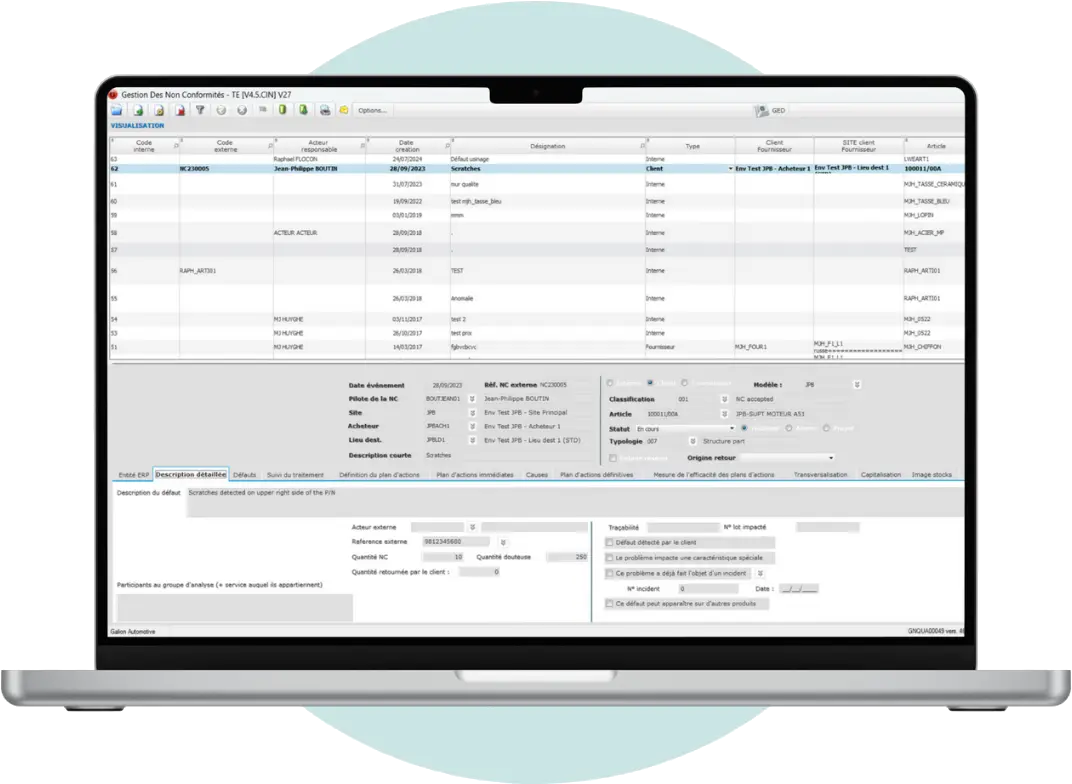

Managing Non-Conformities Effectively

In a demanding industrial context, quality cannot be left to chance. The module Quality Our ERP dedicated to industrial SMEs and mid-caps allows you to structure, track and effectively manage your non-conformities, while limiting their cost and operational impact.

Designed to integrate natively into the ERP environment, the module offers a unified and cross-functional vision of the quality process, from defect detection to the implementation of corrective actions.

Concrete benefits for your business

Reduction of costs related to non-conformities

Rigorous monitoring of actions, precautionary measures and root causes.

Save time in processing quality incidents

Reusable processing models, animated and collaborative quality wall.

Complete traceability

Connection with ERP data (delivery notes, labels, invoices).

Improving customer satisfaction

Personalized quality approach according to the requirements of each client.

Key Features of the Quality module

Interactive quality wall

Personalized action plans

Customer-tailored templates for rapid and standardized processing of non-conformities.

Complete and connected analysis

Monitoring of precautionary measures

Why our GALION ERP is distinguished

Editor-integrator

End-to-end support, from design to operation.

Modular ERP

Activate only the modules you need (quality, MES, EDI, etc.).

Native EDI & MES

Real-time synchronization with production and suppliers.

Traceability

From the defect to the corrective action, in a zero paper approach.

Concrete example: Industrial SME in precision mechanics

Context : A metalworking SME receives a customer complaint about non-compliant parts.

With the Quality module:

- The defect is recorded in the quality wall with supporting photo.

- A corrective action plan is automatically launched based on a specific customer model.

- The precautionary measures (stock blocking, inspection) are immediately applied.

- The link with delivery notes and labels allows the cause to be identified via the ERP.

Result : Reduced processing time by 40 %, improved customer relations and reduced non-quality costs.

Ready to move to more efficient industrial quality management?

Don't let non-conformities impact your profitability. Optimize your quality processes with an ERP designed for industry.

Also discover: ERP SALES

Manage your sales with agility

Improve your sales performance and save time on invoicing.

- Open and closed orders

- Centralized sales forecasts

- Fast billing (immediate, deferred or retroactive)

- Accurate budgeting

- Automatic generation of DESADV